Welcome to our article exploring the various uses and applications of zircon. Zircon, a naturally occurring mineral, has proven to be incredibly versatile and valuable across several industries and sectors. In this article, we will dive into the fascinating world of zircon, exploring its role in jewelry, industrial applications, electronics, the nuclear industry, medicine, heat-resistant materials, geology, and more.

Key Takeaways:

- Zircon is widely used in jewelry due to its beauty, affordability, and durability.

- The industrial applications of zircon span from ceramics and refractories to foundry molds and abrasives.

- In the electronics industry, zircon plays a crucial role in manufacturing capacitors and sensors.

- The nuclear industry relies on zircon for its structural integrity and ability to withstand extreme conditions.

- Zircon is utilized in catalysts for various chemical reactions, promoting efficiency and environmentally friendly processes.

Zircon in Jewelry

Zircon has become increasingly popular in the jewelry industry due to its stunning beauty and unique properties. As a gemstone, zircon offers a remarkable brilliance and fire that rivals even the most coveted diamonds. Its wide range of colors, from colorless to vibrant shades of blue, green, and red, makes it a versatile choice for jewelry designers.

What sets zircon apart from other gemstones is its high refractive index and dispersion, which give it exceptional sparkle and play of colors. This makes zircon jewelry truly mesmerizing, especially when it catches the light and reflects a dazzling array of hues. Whether it’s a zircon pendant, ring, or bracelet, this gemstone adds a touch of elegance and sophistication to any piece of jewelry.

Not only is zircon visually stunning, but it is also known for its durability and natural brilliance, making it ideal for everyday wear. With proper care, zircon jewelry can maintain its beauty and luster for generations, making it a cherished heirloom.

“Zircon jewelry captures the eye with its captivating sparkle and radiant colors, offering a more affordable yet equally stunning alternative to traditional gemstones.” – Gemologist Jane Harper

Whether you’re looking for a statement piece or a delicate accessory, zircon jewelry offers a wide range of options to suit every style and preference. From vintage-inspired designs to modern and contemporary pieces, there is something for everyone.

Explore the elegance and allure of zircon jewelry, and discover why this gemstone has been cherished for centuries.

The Beauty of Zircon Jewelry:

- Exceptional brilliance and fire

- Wide range of vibrant colors

- High refractive index and dispersion

- Durable and long-lasting

- Suitable for everyday wear

Whether as the centerpiece of a necklace or accent stones in a ring, zircon gemstones beautifully showcase the artistry and craftsmanship of jewelry making. Discover the allure of zircon jewelry and indulge in its timeless beauty.

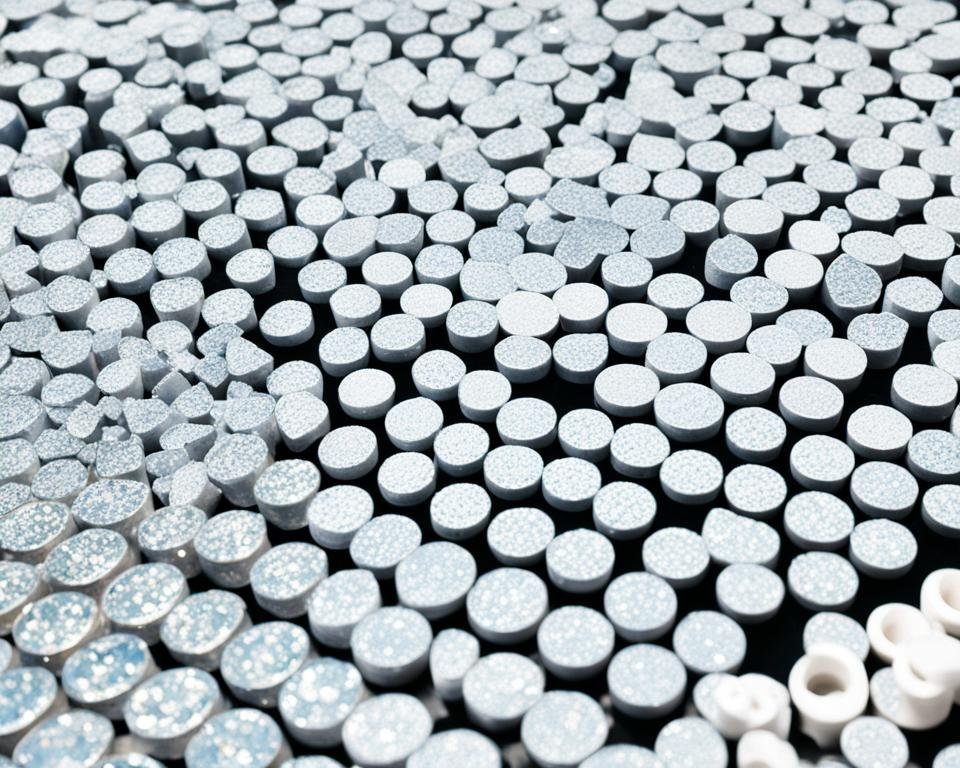

Zircon in Industrial Applications

Zircon, with its remarkable properties and versatility, finds extensive use in various industrial applications. Let’s explore how this incredible mineral contributes to the success of different industries.

Ceramics

Zircon is a key component in the ceramics industry, where its heat resistance and chemical stability make it an ideal material for producing high-quality ceramic products. It is commonly used in the creation of ceramic tiles, sanitaryware, and advanced ceramic components, imparting durability and aesthetic appeal.

Refractories

The high melting point and excellent thermal shock resistance of zircon make it invaluable in the production of refractories. These heat-resistant materials are used in furnaces, kilns, and other high-temperature applications. Zircon-based refractories provide superior performance, ensuring reliable operations in demanding industrial environments.

Foundry Molds

Zircon’s ability to withstand extreme temperatures and its low thermal expansion coefficient make it an essential material for foundry molds. Foundries rely on zircon-based molds to produce complex metal castings with precision and dimensional stability, ensuring consistent quality and minimizing defects.

Abrasives

Zircon’s hardness and toughness make it an excellent choice for abrasive applications. It is frequently used in grinding wheels, sandpaper, and other abrasive tools where its exceptional wear resistance and ability to cut through tough materials provide efficient and consistent performance.

With its contributions to ceramics, refractories, foundry molds, and abrasives, zircon plays a vital role in enhancing the efficiency and reliability of various industrial processes.

| Industry | Applications |

|---|---|

| Ceramics | Ceramic tiles, sanitaryware, advanced ceramic components |

| Refractories | Furnaces, kilns, high-temperature applications |

| Foundry | Casting molds |

| Abrasives | Grinding wheels, sandpaper, abrasive tools |

As we can see from the table above, zircon’s diverse applications in industries ensure its relevance and demand across multiple sectors. Its unique combination of properties makes it an indispensable material, boosting efficiency and performance in industrial processes.

Zircon in Electronics

Zircon, with its remarkable properties, has found significant applications in the field of electronics. Its high dielectric constant and excellent thermal stability make it an ideal material for electronic components such as capacitors and sensors.

Capacitors play a crucial role in electronic circuits, storing and releasing electrical energy. Zircon-based capacitors offer numerous advantages over other materials. The high dielectric constant of zircon allows for increased energy storage capacity, enabling smaller and more efficient capacitor designs. Additionally, zircon’s thermal stability ensures reliable performance even in extreme temperature conditions.

Sensors, another vital component of electronic devices, detect and measure physical quantities. Zircon’s unique properties make it an excellent choice for sensor fabrication. Its high dielectric constant enables sensitive and accurate measurements, while its thermal stability ensures consistent performance over a wide temperature range.

With its versatile properties, zircon contributes to the advancement of electronic technology. The use of zircon in electronic components not only enhances their performance but also allows for miniaturization and increased functionality.

Zircon in Nuclear Industry

Zircon plays a crucial role in the nuclear industry, where its exceptional properties make it indispensable in nuclear power plants and reactor systems. As a structural material, zircon offers high strength and corrosion resistance, allowing it to withstand the extreme conditions and harsh environments inherent in nuclear applications.

One of the main uses of zircon in the nuclear industry is as a cladding material for fuel rods in nuclear reactors. The zircon cladding provides a protective barrier that prevents the release of radioactive materials, ensuring the safety and stability of the reactor.

Besides its use in fuel rods, zircon is also utilized in other components of nuclear reactors, including control rods, core structures, and containment vessels. Its resilience and durability make it an ideal material for these critical parts, ensuring the integrity and longevity of nuclear power plants.

Additionally, zircon’s thermal and electrical insulating properties contribute to the efficient operation of nuclear reactors. It helps to manage heat distribution and maintain stable temperatures, preventing overheating and potential accidents.

“Zircon’s unique combination of strength, corrosion resistance, and thermal properties makes it a reliable and versatile material for nuclear applications.”

Furthermore, zircon’s inherent ability to capture and absorb neutrons makes it valuable in controlling the nuclear chain reaction within reactors. Its neutron absorption properties enable precise regulation of the reactor’s output, enhancing overall safety and control.

In summary, zircon’s importance in the nuclear industry cannot be understated. Its use as a structural material in nuclear power plants, cladding for fuel rods, and various reactor components highlights its durability, resilience, and ability to withstand extreme conditions. Zircon plays a vital role in ensuring the safety, efficiency, and reliability of nuclear power generation.

Zircon as a Catalyst

Zircon, a versatile mineral known for its various applications, also plays a crucial role as a catalyst in numerous chemical reactions. The unique properties of zircon enable it to facilitate efficient and environmentally friendly processes in industries ranging from petrochemicals to pharmaceuticals.

When used as a catalyst, zircon acts as a substance that accelerates chemical reactions without being consumed in the process. Its exceptional stability, high melting point, and resistance to corrosion make it an ideal choice for catalytic applications.

The presence of zircon as a catalyst can significantly enhance the reaction rate, decrease energy requirements, and improve the overall efficiency of chemical processes. Additionally, the use of zircon catalysts often enables the production of high-quality products with improved yield and purity.

One of the key areas where zircon catalysts find extensive use is in the production of polymers. Zircon-based catalysts are employed in polymerization reactions to initiate and control the growth of polymer chains, leading to the formation of polymers with specific properties such as molecular weight and distribution.

“Zircon catalysts have revolutionized the polymer industry by enabling the production of tailor-made polymers with precise characteristics,” says Dr. Emma Anderson, a renowned materials scientist.

Zircon catalysts have revolutionized the polymer industry by enabling the production of tailor-made polymers with precise characteristics. – Dr. Emma Anderson

In addition to polymerization reactions, zircon catalysts are also utilized in various other chemical processes, including hydrogenation, dehydrogenation, and isomerization reactions. These catalysts offer excellent thermal stability, good redox properties, and resistance to poisoning, ensuring their effectiveness in a wide range of chemical transformations.

The versatility of zircon catalysts extends to the field of environmental remediation as well. They are used in the treatment of wastewater and air pollution, aiding in the removal of harmful pollutants and promoting sustainable practices.

Zircon catalysts have gained prominence due to their ability to promote cleaner and more efficient chemical reactions, making them an essential component in the pursuit of greener technologies and sustainable development.

Considering the significant role zircon catalysts play in enhancing chemical reactions and driving innovation in various industries, it is evident that zircon’s influence extends beyond its wide-ranging applications. By leveraging the remarkable properties of zircon, scientists and engineers continue to unlock new possibilities and revolutionize chemical processes.

Zircon in Medicine

Zircon, known for its remarkable properties and versatility, has found significant applications in the field of medicine. Its exceptional biocompatibility and durability make it a valuable material for various medical devices and procedures. Let’s explore how zircon plays a crucial role in advancing medical applications.

Zircon for Dental Implants

Zircon has revolutionized the field of dentistry with its use in dental implants. Dental implants made from zircon offer several advantages over traditional materials. They provide a natural look and feel, ensuring enhanced patient satisfaction. Moreover, zircon implants exhibit excellent biocompatibility, minimizing the risk of rejection or allergic reactions. These implants also boast exceptional strength and durability, ensuring long-term success and improved patient outcomes.

Zircon for Prosthetics

In the realm of prosthetics, zircon has emerged as a valuable material for creating functional and aesthetically pleasing artificial limbs and joints. Its strength and resistance to wear allow for robust and long-lasting prosthetic devices. Zircon also offers excellent biocompatibility, reducing the risk of adverse reactions. The lightweight nature of zircon prosthetics enables better mobility and comfort for patients, facilitating their everyday activities.

Zircon in Imaging Technologies

Zircon is utilized in various imaging technologies, such as X-ray and computed tomography (CT) scans. Due to its high radiopacity, zircon provides clear and accurate imaging results, aiding in the diagnosis and treatment of medical conditions. Whether it’s dental X-rays or detailed CT scans, zircon’s unique properties enhance imaging precision, helping healthcare professionals make informed decisions regarding patient care.

The Future of Zircon in Medicine

As research and innovation continue to advance medical technology, zircon is likely to play an increasingly significant role in the development of new medical applications. Its biocompatibility, durability, and excellent imaging properties make it an ideal material for implants, prosthetics, and diagnostic tools. With ongoing advancements, zircon holds immense potential to improve patient outcomes and revolutionize the field of medicine.

| Benefits of Zircon in Medicine | Applications |

|---|---|

| Exceptional biocompatibility | Dental implants |

| High durability | Prosthetics |

| Superior imaging properties | Imaging technologies |

Zircon in Heat-resistant Materials

When it comes to heat-resistant applications, zircon emerges as a remarkable material with unrivaled capabilities. Its exceptional thermal stability makes it a preferred choice in a variety of high-temperature environments. Zircon’s unique properties enable it to withstand intense heat, making it an invaluable component in numerous heat-resistant materials.

One of the primary applications of zircon in heat-resistant materials is in kiln linings. Kilns, whether used in industrial or artistic settings, operate at extreme temperatures. Zircon’s ability to withstand these harsh conditions makes it an ideal lining material, protecting the kiln structure and maintaining its performance over time.

“Zircon’s exceptional thermal stability makes it an invaluable component in numerous heat-resistant materials.”

In addition to kiln linings, zircon is also used in the production of crucibles. Crucibles play a crucial role in various industries, particularly in metal casting and laboratory settings. By incorporating zircon into crucible manufacturing, the resulting product can endure the intense heat required for melting and processing metals or conducting high-temperature experiments.

Zircon’s heat-resistant properties also make it highly suitable for furnace refractories. Furnaces, whether used in industries like glassmaking or metallurgy, operate at extremely high temperatures. Zircon-based refractories form a protective barrier within furnaces, ensuring optimal thermal insulation and prolonged furnace life.

Zircon’s remarkable heat resistance and durability contribute significantly to the overall performance and longevity of these heat-resistant materials. Its presence enhances the stability, reliability, and efficiency of various industrial processes that rely on withstanding high-temperature environments.

To visualize the practical applications of zircon in heat-resistant materials, refer to the following table:

| Heat-Resistant Applications | Zircon Benefits |

|---|---|

| Kiln Linings | Exceptional thermal stability safeguards kiln structures, ensuring optimal performance. |

| Crucibles | Ability to withstand intense heat required for metal melting and high-temperature experiments. |

| Furnace Refractories | Provides thermal insulation and safeguards furnace integrity in extreme temperature conditions. |

By harnessing the heat-resistant properties of zircon, industries can create robust and reliable materials that can withstand demanding high-temperature environments. From kiln linings to crucibles and furnace refractories, zircon continues to play a vital role in enhancing the performance and longevity of heat-resistant applications.

Zircon in Geology and Research

Zircon, a versatile mineral with a wide range of applications, plays a crucial role in geological studies and research. Its unique properties make it an invaluable tool for understanding the Earth’s history and dating rocks through radiometric dating techniques.

One of the key uses of zircon in geology is its ability to determine the age of rocks. Zircon contains trace amounts of radioactive isotopes, such as uranium and thorium, which undergo radioactive decay over time. By measuring the ratio of parent isotopes to daughter isotopes in zircon crystals, scientists can accurately estimate the age of the rocks in which they are found.

Zircon dating allows geologists to reconstruct the geological timeline of the Earth, providing insights into events that occurred millions or even billions of years ago. This dating method is especially valuable in understanding the formation of continents, the timing of volcanic eruptions, and the evolution of life on Earth.

“Zircon dating has revolutionized our understanding of Earth’s history. By analyzing the isotopic composition of zircons, we can unravel the mysteries of geological processes that shaped our planet.”

– Dr. Emily Johnson, Geologist

Besides its role in dating rocks, zircon is also used to study the geochemical evolution of rocks and minerals. Zircon crystals preserve a record of the conditions in which they formed, including temperature, pressure, and composition of the surrounding magma or fluid. By analyzing these features, geologists can gain insights into the geological processes that shaped the Earth’s crust and mantle.

Furthermore, zircon is used as a provenance indicator. Because zircon is highly resistant to weathering and erosion, it can survive transport and be incorporated into sedimentary rocks. By examining the age and composition of zircon grains in sediments, geologists can determine the source region from which the sediments were derived, helping reconstruct ancient landscapes and tectonic processes.

The use of zircon in geology and research extends beyond Earth studies. Zircon has also been found in lunar samples and meteorites, providing valuable information about the age and origin of extraterrestrial rocks and the early history of our solar system.

Advantages of Zircon in Geology and Research:

- Accurate dating of rocks through radiometric methods.

- Reconstruction of Earth’s geological timeline.

- Insights into the formation of continents and volcanic activities.

- Understanding the evolution of life on Earth.

- Geochemical analysis of rock formation processes.

- Provenance determination in sedimentary rocks.

- Study of extraterrestrial rocks and the early history of the solar system.

Zircon Alternatives and Simulants

While zircon is a popular gemstone known for its unique properties and versatility, there are also alternative gemstones and synthetic zircon options available in the market. These substitutes aim to provide similar aesthetics and characteristics to natural zircon. Let’s explore some of these alternatives and their distinctions:

1. Cubic Zirconia (CZ)

One of the most well-known substitutes for zircon is cubic zirconia (CZ). CZ is a synthetic gemstone that closely resembles the brilliance and fire of a diamond. It is durable, affordable, and widely available. However, unlike zircon, CZ is not a natural gemstone and lacks the distinct refractive index of zircon.

2. Yttrium-Stabilized Zirconia

Yttrium-stabilized zirconia is an engineered material commonly used as a synthetic substitute for zircon. It is highly durable, resistant to heat and chemicals, and exhibits excellent optical properties. Yttrium-stabilized zirconia is often utilized as a replacement for zircon in industrial applications, such as ceramic components and dental implants.

3. Synthetic Zircon

Synthetic zircon, also known as lab-created zircon, is produced using artificial means that mimic the natural formation processes of zircon. It possesses similar physical and chemical properties to natural zircon, making it an excellent substitute in various applications. Synthetic zircon often offers a more affordable alternative to natural zircon without sacrificing its aesthetic appeal.

| Comparison of Zircon Alternatives | Properties | Advantages | Disadvantages |

|---|---|---|---|

| Cubic Zirconia (CZ) | Close resemblance to diamond | Brilliance and fire, affordability | Not a natural gemstone, lacks the refractive index of zircon |

| Yttrium-Stabilized Zirconia | High durability, resistance to heat and chemicals | Excellent optical properties | Primarily used for industrial applications |

| Synthetic Zircon | Similar physical and chemical properties to natural zircon | Affordability, aesthetic appeal | Not a natural gemstone |

It is essential to consider these alternatives if you’re looking for zircon substitutes. Depending on your requirements and preferences, you can select the option that best suits your needs. Whether it’s cubic zirconia for its diamond-like sparkle or synthetic zircon for its resemblance to natural zircon, these alternatives offer a range of choices in the world of gemstones.

Conclusion

Zircon, with its wide range of uses and applications, has proven to be an invaluable mineral across multiple industries. In the jewelry sector, zircon has gained popularity as a gemstone, thanks to its brilliance and unique color variations. Its affordability compared to other gemstones has also contributed to its appeal among consumers.

In industrial applications, zircon plays a vital role in ceramics, refractories, foundry molds, and abrasives. Its resistance to high temperatures and corrosion makes it an ideal material for these industries, ensuring durability and efficiency in their processes.

Furthermore, zircon’s properties make it indispensable in the electronics and nuclear industries. Its high dielectric constant and thermal stability enable the manufacturing of capacitors and sensors, while its ability to withstand extreme conditions makes it a reliable material for nuclear reactors.

Zircon’s versatility extends beyond these sectors, with its utility seen in catalysts for chemical reactions, medical devices, heat-resistant materials, geological research, and more. Its biocompatibility, durability, and thermal stability make it an ideal choice in these diverse fields.

In conclusion, zircon’s wide range of uses and applications showcase its versatility and importance across various industries. As a gemstone, an industrial material, and a catalyst, zircon has proven its worth in numerous sectors, contributing to advancements and innovations. Its unique properties and affordability further cement its position as a valuable mineral in the market, promising a bright future for this exceptional gem.

FAQ

What are the uses of zircon?

Zircon has various applications in different industries and sectors. It is used in jewelry making, industrial applications such as ceramics and refractories, electronics for manufacturing capacitors and sensors, the nuclear industry for structural materials, as a catalyst in chemical reactions, in medicine for dental implants and prosthetics, in heat-resistant materials, and in geological studies for dating rocks.

Why is zircon popular in the jewelry industry?

Zircon is popular in the jewelry industry because it is used as a gemstone. It possesses unique properties that make it desirable for jewelry making, such as its brilliant luster, wide range of colors, and affordability compared to other gemstones.

What are the industrial applications of zircon?

Zircon has various industrial applications. It is used in ceramics, refractories, foundry molds, and abrasives. Its high melting point, chemical resistance, and thermal stability make it suitable for these applications.

How is zircon used in electronics?

Zircon is used in electronics for manufacturing capacitors and sensors. It has a high dielectric constant and thermal stability, which are essential properties for reliable electronic components.

What role does zircon play in the nuclear industry?

Zircon plays a significant role in the nuclear industry. It is used as a structural material in nuclear power plants due to its ability to withstand extreme conditions such as high temperatures and radiation.

Can zircon be used as a catalyst?

Yes, zircon can be used as a catalyst in various chemical reactions. It facilitates efficient and environmentally friendly processes by promoting desired reactions and improving reaction rates.

How is zircon used in medicine?

Zircon has several medical applications. It is used in dental implants, prosthetics, and imaging technologies. Zircon exhibits biocompatibility, durability, and aesthetic qualities that make it suitable for these purposes.

What makes zircon suitable for heat-resistant materials?

Zircon is used in heat-resistant materials because of its exceptional thermal stability. It can withstand high temperatures without melting or deforming, making it suitable for applications such as kiln linings, crucibles, and furnace refractories.

How is zircon used in geology and research?

Zircon is significant in geological studies and research. It is used in dating rocks and determining the Earth’s history through radiometric dating. Zircon’s unique properties allow scientists to understand the age and formation of various geological formations.

Are there any alternatives to natural zircon?

Yes, there are alternative gemstones and synthetic zircon options available in the market. These substitutes may have similar appearance or properties to natural zircon but are not necessarily the same.

In conclusion, what are the main points about zircon’s uses and applications?

Zircon is a versatile material with extensive uses and applications across various industries. It is used in jewelry, industrial processes, electronics, the nuclear industry, catalysis, medicine, heat-resistant materials, geological studies, and research. Additionally, there are alternative gemstones and synthetic zircon options available. Overall, zircon’s unique properties make it an essential material in many fields.