Welcome to our article exploring the diverse uses of zirconium, a remarkable metal with a wide range of applications. Zirconium, known for its exceptional strength, corrosion resistance, and heat tolerance, has found its place in various industries, from aerospace and nuclear power to medical and chemical processing.

Throughout this article, we will delve into the unique properties of zirconium and its crucial role in different sectors. Join us as we explore how zirconium contributes to technological advancements and supports innovation across various fields.

Key Takeaways:

- Zirconium is a versatile metal used in multiple industries

- Its exceptional strength and corrosion resistance make it ideal for applications in aerospace, nuclear power, and chemical processing

- Zirconium’s non-allergenic properties have made it a popular choice for medical implants and prosthetics

- In the field of optics, zirconium is utilized in lenses, camera bodies, and optical coatings

- Zirconium serves as a catalyst in various chemical reactions, enhancing reaction rates and selectivity

Zirconium in Aerospace and Aviation

Zirconium plays a crucial role in the aerospace and aviation industries, contributing to the manufacturing of lightweight and heat-resistant components. Its exceptional properties make it an ideal choice for various applications in this field.

One of the key areas where zirconium shines is in the production of jet engine parts. These engines operate under extreme conditions, requiring materials that can withstand high temperatures and pressures. Zirconium alloys offer exceptional heat resistance, making them suitable for components such as turbine blades and combustors.

Furthermore, zirconium is used in the construction of aircraft structures, ensuring strength, durability, and weight reduction. Its low density allows for the creation of lightweight structures without compromising strength and integrity. This translates to improved fuel efficiency and enhanced overall performance.

By incorporating zirconium into their designs, aerospace and aviation manufacturers can achieve optimal performance while maximizing fuel efficiency. The unique qualities of zirconium, such as its high melting point, corrosion resistance, and low neutron absorption, make it a valuable material in these industries.

Zirconium in Advanced Ceramics

Zirconium plays a crucial role in the world of advanced ceramics, bringing forth remarkable improvements in strength and durability. As a reinforcing agent, zirconium enhances the structural integrity of ceramic materials, making them highly resilient to extreme conditions and mechanical stresses. This has significant implications for industries such as electronics and energy production, where advanced ceramics are increasingly employed.

The incorporation of zirconium in ceramic matrices increases fracture toughness and resistance to wear, resulting in materials that can withstand harsh operating environments. The exceptional heat resistance of zirconium in ceramics allows for application in thermally demanding processes, such as aerospace and defense technologies and automotive components.

“The addition of zirconium nanoparticles to ceramic matrices has revolutionized the field of advanced ceramics, opening up new possibilities for innovation and progress.”

Zirconium-containing ceramics find applications in various fields, including:

- Electronics: Zirconium-based ceramics are used in the production of substrates, circuit boards, and electronic components due to their excellent electrical insulation properties and resistance to high temperatures.

- Energy Generation: Zirconium ceramics play a vital role in energy production systems, including solid oxide fuel cells (SOFCs) and gas turbines, as they can withstand high temperatures and exhibit ionic conductivity. Zirconium-based materials also contribute to the efficient production of solar cells.

- Chemical Industry: Zirconium ceramics are utilized in corrosive environments, such as chemical processing plants, where their resistance to chemical attack and stability make them ideal materials for reactors, vessels, and piping.

Enhancing Efficiency with Zirconium

The utilization of zirconium in advanced ceramics significantly enhances the efficiency and performance of various technologies. Its unique properties make it a preferred choice for a wide range of applications.

| Industry | Application | Benefits of Zirconium |

|---|---|---|

| Electronics | Substrates, circuit boards, and electronic components | Excellent electrical insulation properties, high-temperature resistance |

| Energy Generation | Solid oxide fuel cells, gas turbines, and solar cells | High-temperature resistance, ionic conductivity |

| Chemical Industry | Reactors, vessels, and piping | Resistance to chemical attack, stability |

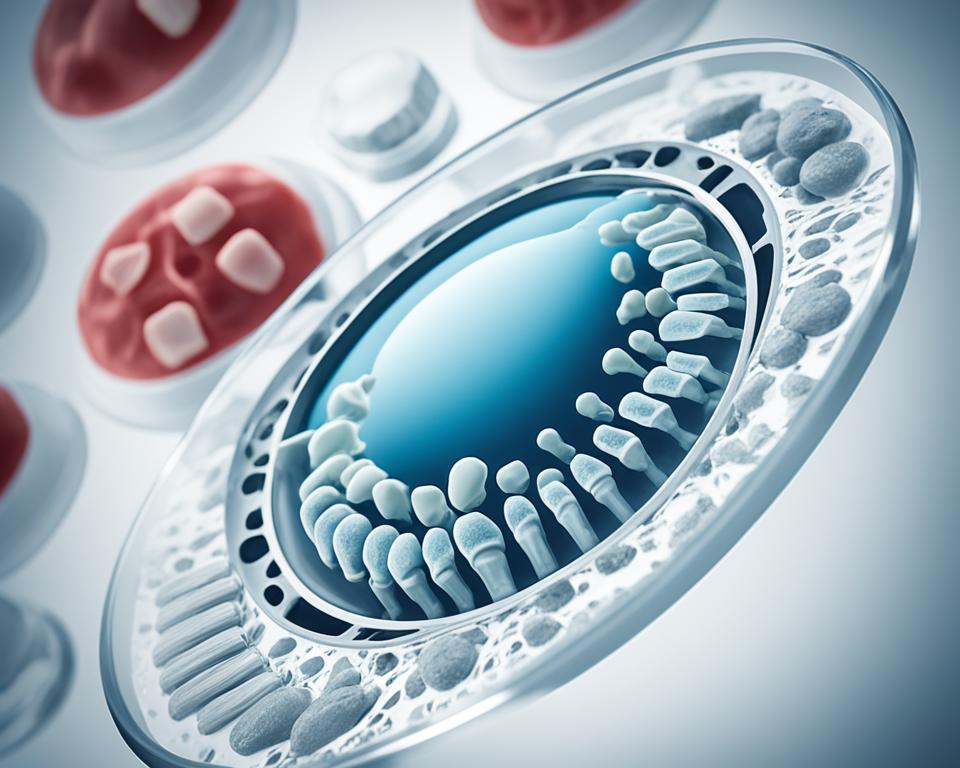

Zirconium in Nuclear Power

Zirconium plays a critical role in the field of nuclear power, where safety and efficiency are of paramount importance. One of the prominent applications of zirconium in nuclear power is as a cladding material for nuclear fuel rods.

The zirconium cladding provides a protective barrier around the nuclear fuel, preventing the release of radioactive materials and ensuring the integrity of the fuel rods. Its exceptional corrosion resistance and high melting point make zirconium an ideal choice for this demanding application. In addition, zirconium’s low neutron absorption properties enable efficient neutron moderation and help maintain the stability of nuclear reactors.

“Zirconium cladding has been extensively used in nuclear reactors for decades due to its exceptional properties and its ability to withstand extreme environments.”

The use of zirconium cladding allows for the safe operation of nuclear reactors by maintaining the structural integrity of the fuel rods even under high temperatures and irradiation. This reliability is crucial in preventing fuel failure and minimizing the risk of nuclear accidents.

Furthermore, zirconium’s compatibility with other nuclear reactor materials and its favorable mechanical properties make it an essential component in the fabrication of nuclear fuel assemblies. Its excellent thermal conductivity ensures efficient heat transfer from the nuclear fuel to the coolant, contributing to the overall efficiency of the reactor.

The table below summarizes the key properties and advantages of zirconium in nuclear power:

| Properties and Advantages of Zirconium in Nuclear Power |

|---|

| Exceptional corrosion resistance |

| High melting point |

| Low neutron absorption properties |

| Provides protective barrier for nuclear fuel |

| Maintains structural integrity of fuel rods |

| Enables efficient heat transfer in reactors |

This table highlights the remarkable properties of zirconium that make it indispensable in nuclear power applications. From its ability to resist corrosion to its crucial role in maintaining the structural integrity of fuel rods, zirconium’s contributions to the safe and efficient operation of nuclear reactors cannot be overstated.

Through its use in nuclear power, zirconium continues to demonstrate its enduring value as a critical material in the pursuit of clean and sustainable energy sources.

Zirconium in Chemical Processing

In the realm of chemical processing, zirconium plays a vital role as a versatile and reliable material. With its exceptional corrosion resistance, stability, and compatibility with various chemicals, zirconium has become a go-to choice for equipment used in the chemical industry.

Chemical processing involves handling and manipulating substances that are often aggressive and corrosive. This is where zirconium truly shines, as it possesses remarkable resistance to chemical attacks, even in highly acidic or alkaline environments. Unlike other metals, zirconium does not readily react with chemicals, ensuring the integrity and longevity of the equipment it is used in.

Moreover, zirconium’s stability allows it to withstand extreme temperatures, making it suitable for applications that involve high heat or cryogenic processes. Whether it’s heat exchangers, reactors, or storage tanks, zirconium’s ability to maintain structural integrity and performance under extreme conditions is unparalleled.

Table: Applications of Zirconium in Chemical Processing

| Equipment | Application |

|---|---|

| Heat exchangers | Efficient heat transfer in the production of chemicals, petrochemicals, and pharmaceuticals |

| Reactors | Safe containment and controlled reactions for manufacturing various chemical compounds |

| Storage tanks | Durable and corrosion-resistant vessels for storing corrosive chemicals and hazardous materials |

| Piping systems | Reliable transport of corrosive fluids and gases without the risk of contamination |

| Distillation columns | Efficient separation and purification of chemical compounds through distillation processes |

Zirconium’s compatibility with various chemicals expands the possibilities for the chemical industry, enabling the production of a wide range of compounds, from pharmaceuticals to polymers. Its resistance to chemical corrosion ensures the purity and quality of final products, contributing to the overall efficiency of the chemical manufacturing process.

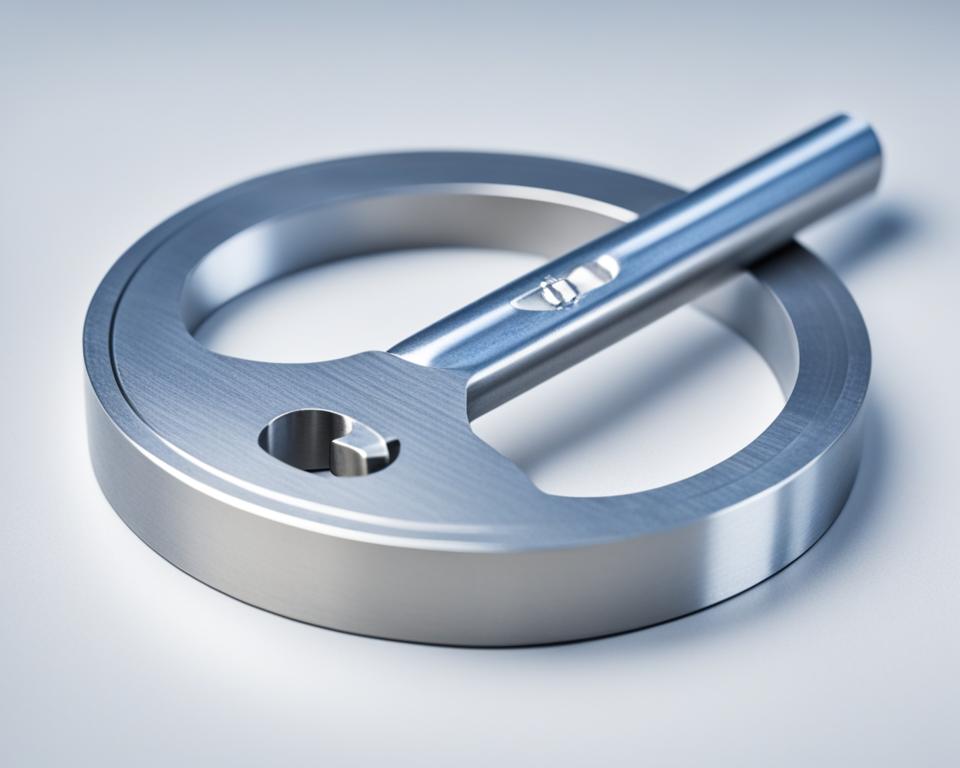

Zirconium in Medical Implants

When it comes to cutting-edge medical applications, zirconium plays a vital role. This remarkable metal exhibits exceptional properties such as biocompatibility, low toxicity, and non-allergenicity, making it an ideal material for a wide range of medical implants.

Zirconium has gained significant recognition in orthopedic medicine for its ability to enhance the performance and longevity of joint implants. Its remarkable strength, corrosion resistance, and biocompatibility provide a substantial advantage in orthopedic surgeries, allowing patients to regain mobility and improve their quality of life.

Moreover, zirconium offers immense opportunities in restorative dentistry, specifically dental implants and prosthetics. Its biocompatibility ensures a well-tolerated interface between the implant and the surrounding tissue, minimizing the risk of adverse reactions or inflammation. This makes zirconium an excellent choice for dental restorations that require long-term stability and durability.

“Zirconium implants have revolutionized the field of orthopedics and restorative dentistry. They offer exceptional performance, longevity, and patient satisfaction, making them an indispensable tool for healthcare professionals.”

In addition to orthopedic and dental applications, zirconium finds significant use in various other medical implants, including cardiac pacemakers, cochlear implants, and prosthetic limbs. Its versatile nature, coupled with its biocompatibility and low toxicity, makes zirconium a preferred choice for implanted medical devices.

To provide a comprehensive overview, here are some notable advantages and applications of zirconium in medical implants:

| Advantages of Zirconium in Medical Implants | Applications |

|---|---|

| Biocompatibility | Orthopedic implants |

| Low toxicity | Dental restorations |

| Non-allergenicity | Cardiac pacemakers |

| Corrosion resistance | Cochlear implants |

| Enhanced performance and longevity | Prosthetic limbs |

As medical technology continues to advance, zirconium’s unique properties and its compatibility with the human body have positioned it as a valuable material for innovative implant solutions. Its contribution to improving patient outcomes and enhancing quality of life cannot be overstated.

Zirconium in Optical Devices

Zirconium plays a crucial role in the advancement of optical devices, revolutionizing various fields like photography and telecommunications. Its unique properties make it highly sought-after for creating high-performance optical systems.

One of the key applications of zirconium in optical devices is in the production of lenses. Zirconium-based glass materials, such as zirconia and zirconium oxide, exhibit excellent optical clarity and low dispersion, allowing for the creation of lenses with exceptional image quality and minimal color aberrations.

Zirconium is also used in the construction of camera bodies, providing lightweight and durable components for professional cameras. Its high strength-to-weight ratio makes it an ideal choice, enabling photographers to capture stunning images without compromising on the camera’s structural integrity.

Furthermore, zirconium-based coatings are applied to optical devices to enhance their performance. These coatings improve light transmission, reduce glare, and increase scratch resistance, resulting in sharper and clearer images.

Advantages of Zirconium in Optical Devices

- Exceptional image quality: Zirconium lenses provide high-resolution images with minimal distortions or chromatic aberrations.

- Durability: Zirconium camera bodies are lightweight yet robust, ensuring long-lasting performance in demanding conditions.

- Enhanced functionality: Zirconium coatings improve light transmission and reduce reflections, allowing for superior optical performance.

By harnessing the unique properties of zirconium, optical device manufacturers can deliver cutting-edge products that meet the demands of professional photographers, videographers, and telecommunications experts.

“Zirconium’s versatility and optical properties have transformed the way we capture and view the world, enabling us to push the boundaries of creativity and communication.”

– Joshua Miller, Professional Photographer

| Application | Advantages |

|---|---|

| Lenses | Exceptional image quality Low dispersion and color aberrations |

| Camera Bodies | Lightweight and durable High strength-to-weight ratio |

| Optical Coatings | Improved light transmission Reduced glare and scratches |

Zirconium in Catalysts

Zirconium, a versatile metal with exceptional properties, finds extensive use as a catalyst in various chemical reactions. Its unique characteristics make it valuable in industries such as petroleum refining, environmental remediation, and pharmaceutical production. Zirconium-based catalysts play a pivotal role in enhancing reaction rates and selectivity, enabling the efficient synthesis of desired products.

In petroleum refining, zirconium catalysts are employed to improve the production of high-quality fuels and petrochemicals. These catalysts facilitate crucial processes such as hydrocracking and isomerization, leading to cleaner and more efficient fuel production. The catalytic properties of zirconium ensure optimal conversion of crude oil into valuable end products, contributing to the energy industry’s sustainability.

Furthermore, zirconium catalysts are instrumental in environmental remediation, aiding in the removal of harmful pollutants from air and water. These catalysts assist in the breakdown of organic compounds and the reduction of toxic emissions, supporting efforts to mitigate environmental damage. Zirconium’s effectiveness as a catalyst in environmental applications showcases its potential for promoting a cleaner and greener future.

Additionally, the pharmaceutical industry benefits from the use of zirconium catalysts, especially in the synthesis of complex organic molecules. Zirconium-based catalysts enable precise control over chemical reactions, enhancing yields and minimizing unwanted byproducts. This capability is crucial for drug discovery and development, where the efficient synthesis of pharmaceutical intermediates and active compounds is of utmost importance.

The remarkable attributes of zirconium, such as its high thermal stability and resistance to corrosion, make it an ideal choice for catalytic applications. Its compatibility with a wide range of reaction conditions and substrates further enhances its versatility as a catalyst. With ongoing research and development, the potential uses of zirconium in catalysis continue to expand, opening doors to new possibilities in diverse industries.

Zirconium Catalysts in Action

Let’s take a closer look at how zirconium catalysts drive significant advancements in select industries:

- Petroleum Refining: Zirconium catalysts increase the efficiency of hydrocracking processes, enhancing the production of higher-quality fuels and petrochemicals.

- Environmental Remediation: Zirconium catalysts aid in the decomposition of harmful pollutants, leading to cleaner air and water.

- Pharmaceutical Production: Zirconium-based catalysts enable the synthesis of complex organic compounds with high yields and purity, supporting drug discovery and development.

The outstanding performance of zirconium catalysts across these sectors demonstrates their significant contribution to catalytic reactions and their potential for driving innovation and sustainability.

With its wide-ranging applications and catalytic prowess, zirconium continues to shape various industries and propel them towards a more efficient and environmentally conscious future.

Conclusion

In conclusion, zirconium is a remarkable metal with a wide range of applications in various industries. Throughout this article, we have explored the diverse uses and unique properties of zirconium, highlighting its significance and potential for future innovations.

From aerospace and aviation to advanced ceramics, zirconium plays a crucial role in manufacturing lightweight and heat-resistant components, strengthening materials, and enhancing the durability of products. Its presence in nuclear power ensures the safe operation of reactors, while its corrosion resistance makes it invaluable in chemical processing equipment.

In the medical field, zirconium’s biocompatibility and non-allergenic properties make it an ideal material for orthopedic implants, dental restorations, and prosthetics. Additionally, its contributions to optics, catalysts, and various other industries cannot be overlooked.

Overall, zirconium’s versatility and essentiality make it a highly sought-after material with immense potential. As technology continues to advance, we can expect zirconium to play a pivotal role in shaping the future of industries and unlocking new possibilities.

FAQ

What are the uses of zirconium?

Zirconium has numerous applications in various industries. It is used in aerospace and aviation, advanced ceramics, nuclear power, chemical processing, medical implants, optical devices, and catalysts.

Where is zirconium used in aerospace and aviation?

Zirconium is utilized in the manufacturing of lightweight and heat-resistant components in the aerospace and aviation industries. It is used for producing jet engine parts and aircraft structures.

How is zirconium involved in advanced ceramics?

Zirconium plays a crucial role in advanced ceramics by enhancing their strength and durability. It is used as a reinforcing agent in industries such as electronics and energy production.

What is the significance of zirconium in nuclear power?

Zirconium is vital in the nuclear power sector as it is used as a cladding material in nuclear fuel rods. It ensures the safe and efficient operation of nuclear reactors.

How does zirconium contribute to chemical processing?

Zirconium is employed in chemical processing due to its corrosion resistance, stability, and compatibility with various chemicals. This makes it valuable for equipment used in the chemical industry.

How is zirconium used in medical implants?

Zirconium is extensively used in cutting-edge medical applications due to its biocompatibility, low toxicity, and non-allergenic properties. It is used for orthopedic implants, dental restorations, and prosthetics.

Where is zirconium utilized in optical devices?

Zirconium plays a significant role in optical devices, contributing to advancements in optics. It is used in lenses, camera bodies, and optical coatings, enabling high-performance optical systems in photography and telecommunications.

How does zirconium function as a catalyst?

Zirconium serves as a catalyst in various chemical reactions, enhancing reaction rates and selectivity. It finds application in industries such as petroleum refining, environmental remediation, and pharmaceutical production.